We Engineer.

Engineering is at the heart of turning a strong concept into a reliable, high-performing product. Our engineering consultancy supports you with practical expertise and clear problem-solving to make sure your design works in the real world. From early feasibility and technical exploration to detailed development, materials testing, prototyping and manufacturing assistance, we help you move forward with confidence. We keep the process collaborative and easy to understand, so you always feel supported as your product takes shape.

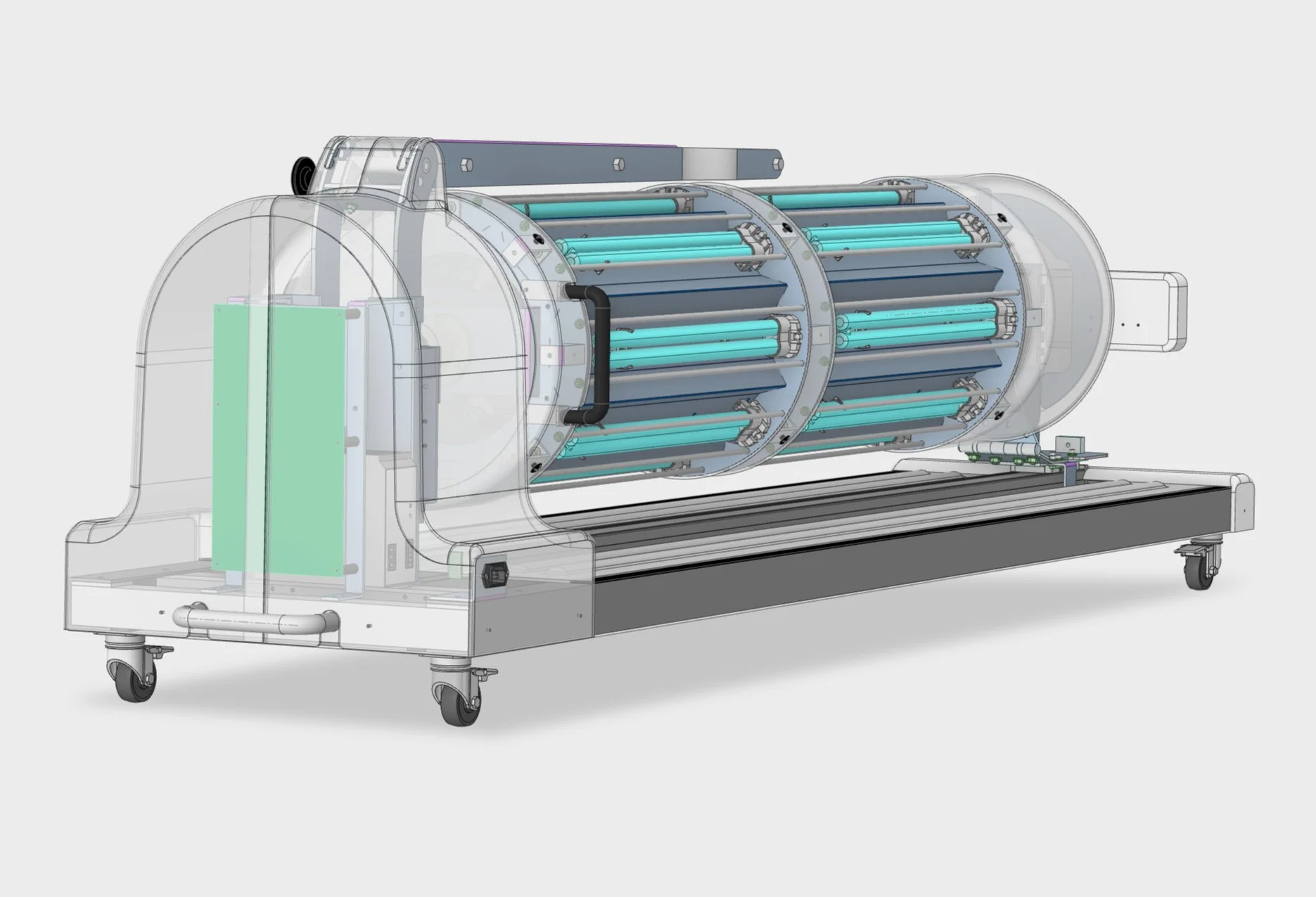

Computer Aided Design (CAD)

CAD is the use of 3D computer technology to aid the design of a part or product. CAD solutions maximise innovation and quality to help create exceptional products. CAD enables engineers to visualise and model a product before it has ever left the drawing board - identifying potential problem areas and getting the product ready for production with only a fraction of the time and money required by traditionally run projects.

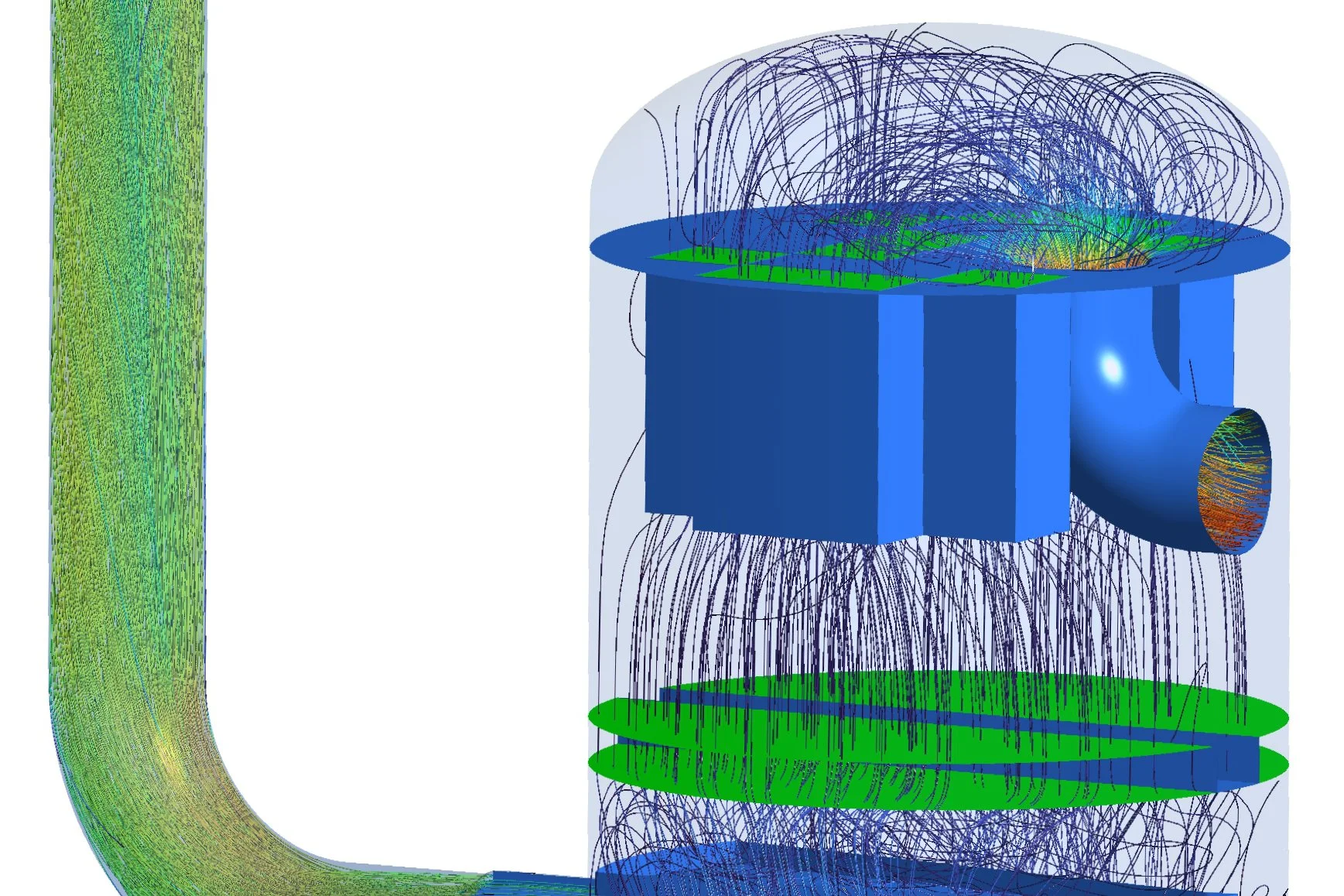

Computational Fluid Dynamics (CFD)

CFD, also referred to as flow simulation, is a computer simulation technique that allows detailed analysis of fluid flow through any product. It allows the fluid mass flow, velocity, density, temperature, pressure, concentration or any derived fluid property to be calculated at all locations within the flow field. The interaction of the fluid with its solid boundaries, such as fluid-dynamic forces and heat transfer rates can also be calculated accurately for use in stress analysis.

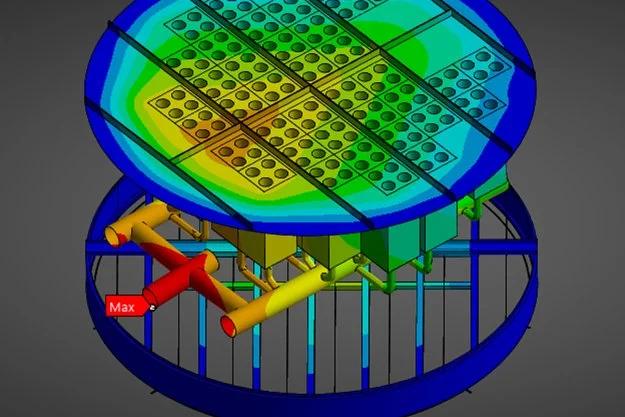

Finite Element Analysis

(FEA)

FEA is used to ensure mechanical integrity by accurately analysing load paths and material stresses. As modern manufacturing methods enable final products to almost have no limitation on form then less rigorous forms of analysis become invalid. FEA can be used for new product or refinement of an existing product and is fast becoming an industry standard. FEA can be taken directly from CFD ensuring that situations not involving simple force or displacement inputs can reflect accurate pressure and thermal distributions.

Process Engineering

Swift TG Solutions provides fully integrated process engineering services to the process industries. We pride ourselves on delivering projects of any scale; from rapid, small‑value tasks to multi‑million‑pound programs.

We support every project stage: Front End Studies, Modelling and Analysis, Detailed Process Design (including the generation of applicable documentation) and we have some specialist capabilities up our sleeve.

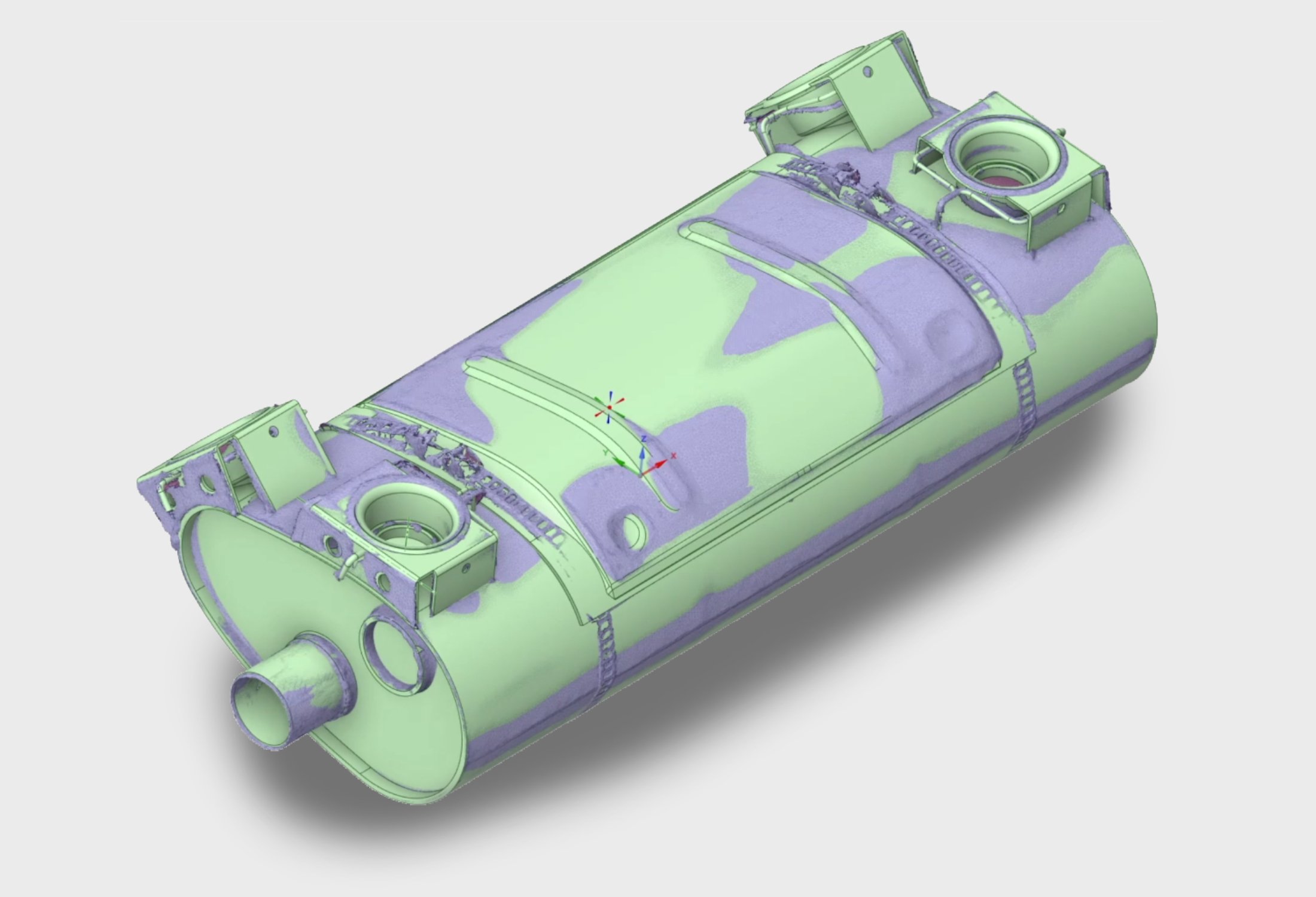

Reverse Engineering & Laser Scanning

Many existing products have been crafted by eye without reference to engineering drawings. However, modifying these products to meet the standards and quality required by today’s market may prove difficult without such information. In these circumstances Reverse Engineering is a technique that can be employed to gather the required data. Swift TG Solutions have the skills and tools, including laser scanning & photogrammetry, to provide the solution you need.

Materials Testing

Swift TG Solutions provides material testing to qualify the best options for a product by predicting and optimising a product’s performance. This will improve and accelerate the manufacturing process.

We can test both metallic and composite materials to determine their suitability for specific applications, ensure they meet quality standards and identify potential defects by compression, hardness, impact and fatigue tests.

Rapid Prototyping &

Manufacturing Support

Swift TG Solutions provides rapid prototyping and manufacturing support to take ideas from concept to production-ready parts.

We combine fast turnaround, practical design-for-manufacture input, and dependable delivery for low-volume builds, trials, and ongoing production requirements.