Heat Exchange Study

Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) for the Onshore Process Industry

Challenge.

A bespoke inline heat‑exchanger was required with tight limits on gas‑side pressure drop and heat‑transfer performance. Installed downstream of gas compressors in a low‑pressure compression train, any incremental pressure loss would directly affect compressor sizing and operating cost.

Approach.

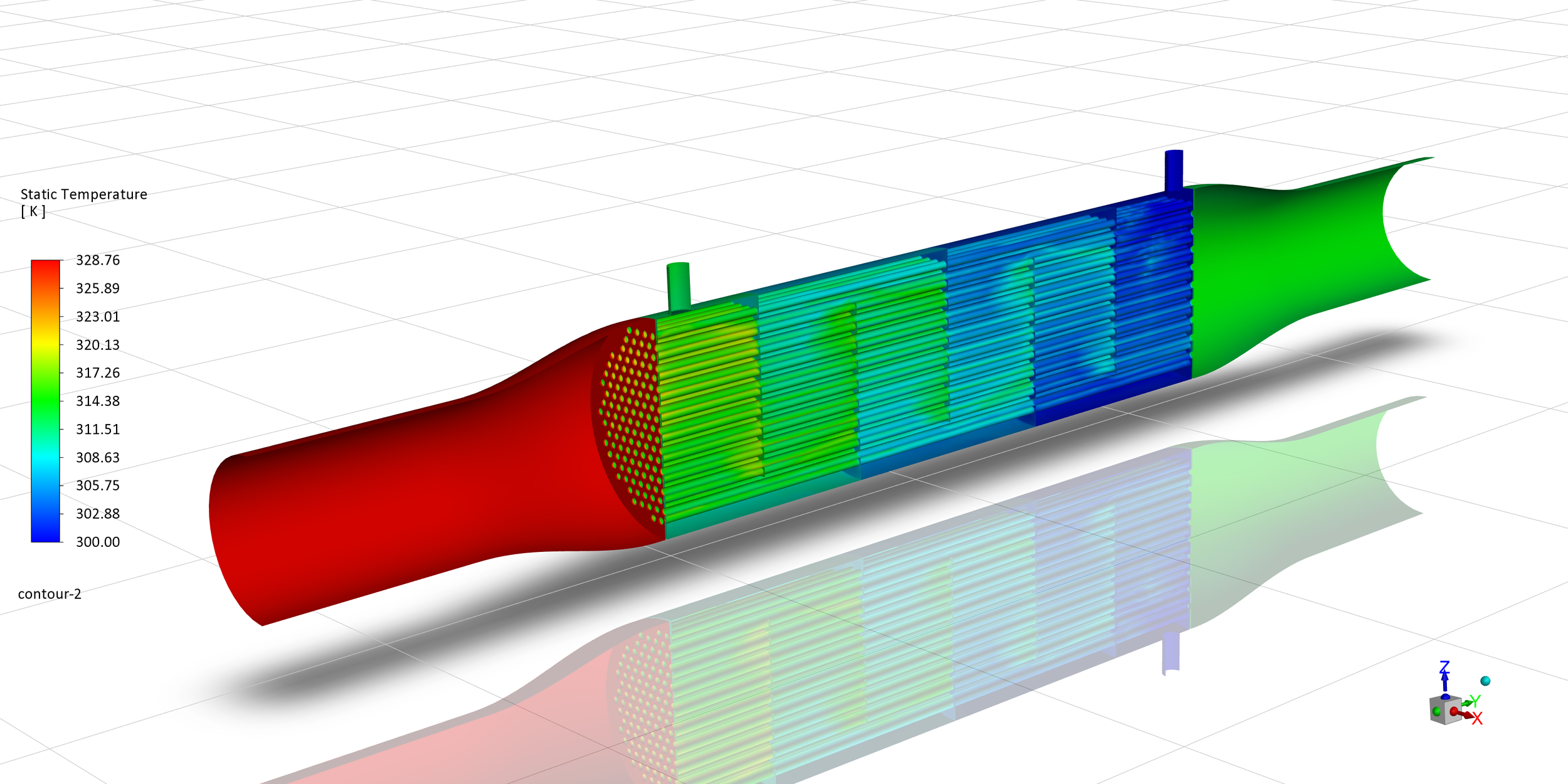

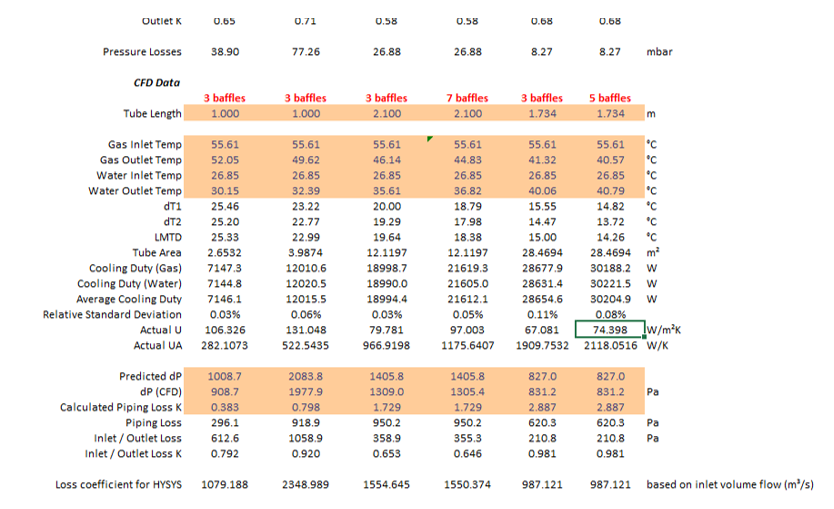

Swift TG Solutions executed a CFD campaign across a suite of candidate geometries, explicitly coupling the gas stream with the water‑coolant circuit to quantify cooling performance and gas‑side pressure drop. Within the CFD framework, gas‑phase properties were modelled using the ideal gas law to capture temperature‑dependent variation. We then benchmarked the results against conventional heat‑exchanger sizing methods, verifying that the final design aligned with established practice.

Validation and Delivery.

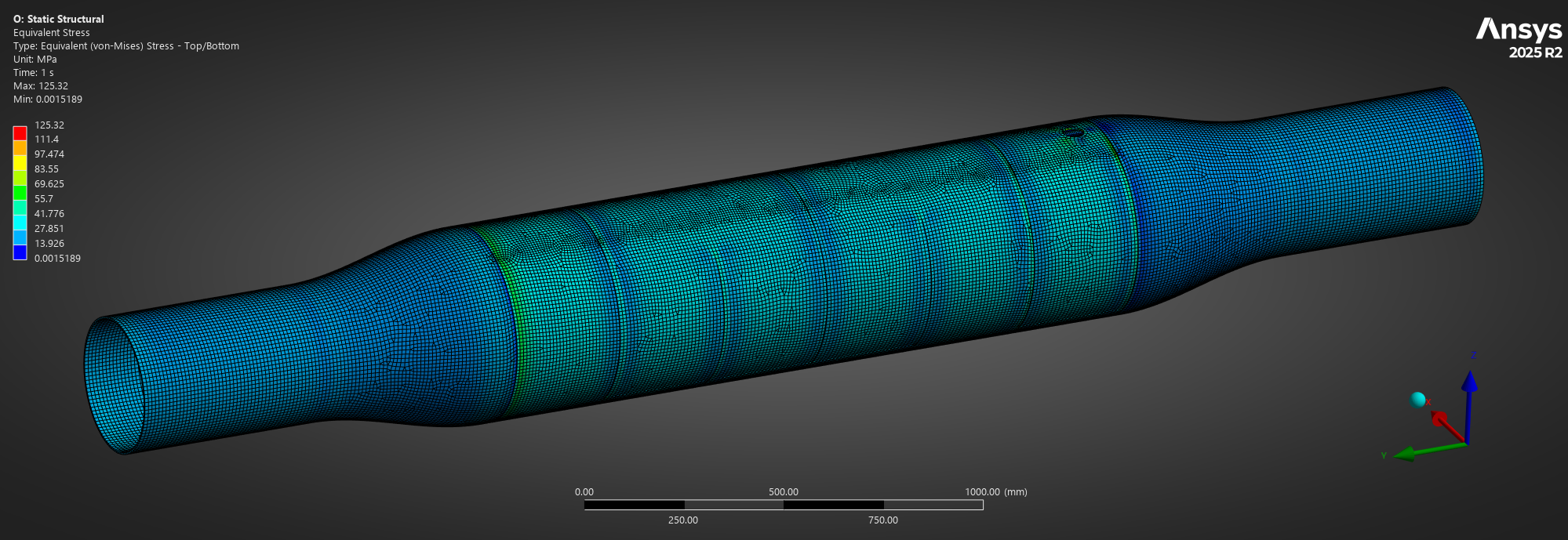

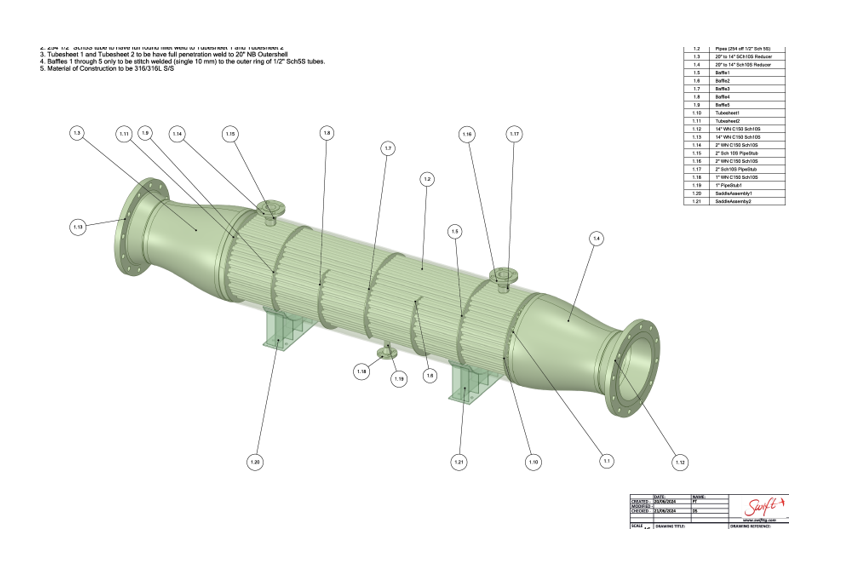

The selected configuration underwent FEA to confirm structural integrity, and we supplied full fabrication drawings for manufacture.

Result.

Units are operational and performing as expected.

Process.

CFD simulations were performed

FEA was performed

Results were post processed

Fabrication drawings were generated

“They understood our priorities and delivered exactly what we needed - on time and with great attention to detail.”