Isovolta Airpreg Tensile and Shear Properties Study

Materials Testing for the Aerospace Industry

Challenge.

To determine the tensile and shear properties of supplied material specimens. The properties to be determined are Young’s Modulus, Shear Modulus of Elasticity (1-2 direction only), Poisson’s Ratio, Ultimate Tensile Strength and Ultimate Shear Strength.

Approach.

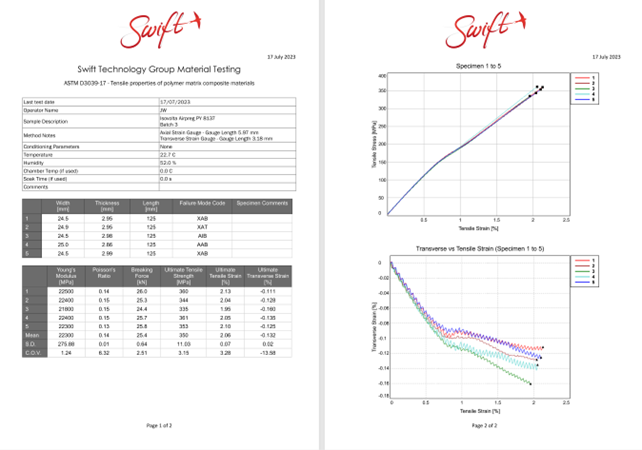

Utilising our Instron 5985 material testing machine, Swift TG Solutions executed a full test run of both tensile and shear samples. Each run consisted of three batches of five specimens each for 15 total specimens tested. Strain gauges were used to determine strains for all specimens. Tensile tests were performed to the ASTM D3039-17 standard, and shear test were performed to the ASTM D7078-12 standard.

Validation and delivery.

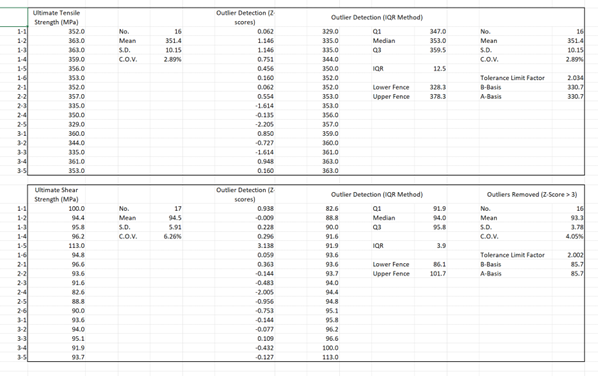

Full post-processing of the results was performed to produce A and B-basis ultimate strength values as well as mean values for Young’s Modulus, Shear Modulus of Elasticity (1-2 direction only) and Poisson’s Ratio. The statistical analysis used included outlier detection using multiple methods and calculation of standard deviation and coefficient of variation as measures of confidence in the results.

Result.

The material properties values determined were within the range of expectation, with the ultimate strengths coming out higher than anticipated. The customer was very happy with the level of confidence found in the results.

Process.

Once the specimens were received from the customer, they were stored in the vicinity of the testing machine for multiple days to allow the specimens to condition.

Once they were conditioned, two strain gauges were bonded to each specimen.

The specimen is then loaded into the testing machine and the loading gradually increased by until the specimen fails, with the machine recording data every second.

The The recorded data is exported for post-processing.

The required properties are then determined from the data using calculations and established statistical techniques

A report is created to summarise all the results, and this is supplied to the customers along with the specimens, photos and all the raw data for complete transparency.

“Swift TG Solutions understood our priorities and delivered exactly what we needed - on time and with great attention to detail.”