Flow Induced Vibration Analysis

Challenge.

The client was experiencing loud vibrations in piping and structure, both upstream and downstream of two large control valves. The valves appeared to be causing the vibrations when partially open, and we were asked to perform modal analysis and harmonic response simulations to determine the structure’s natural frequencies and corresponding modal shapes to identify and eliminate vulnerabilities.

Approach.

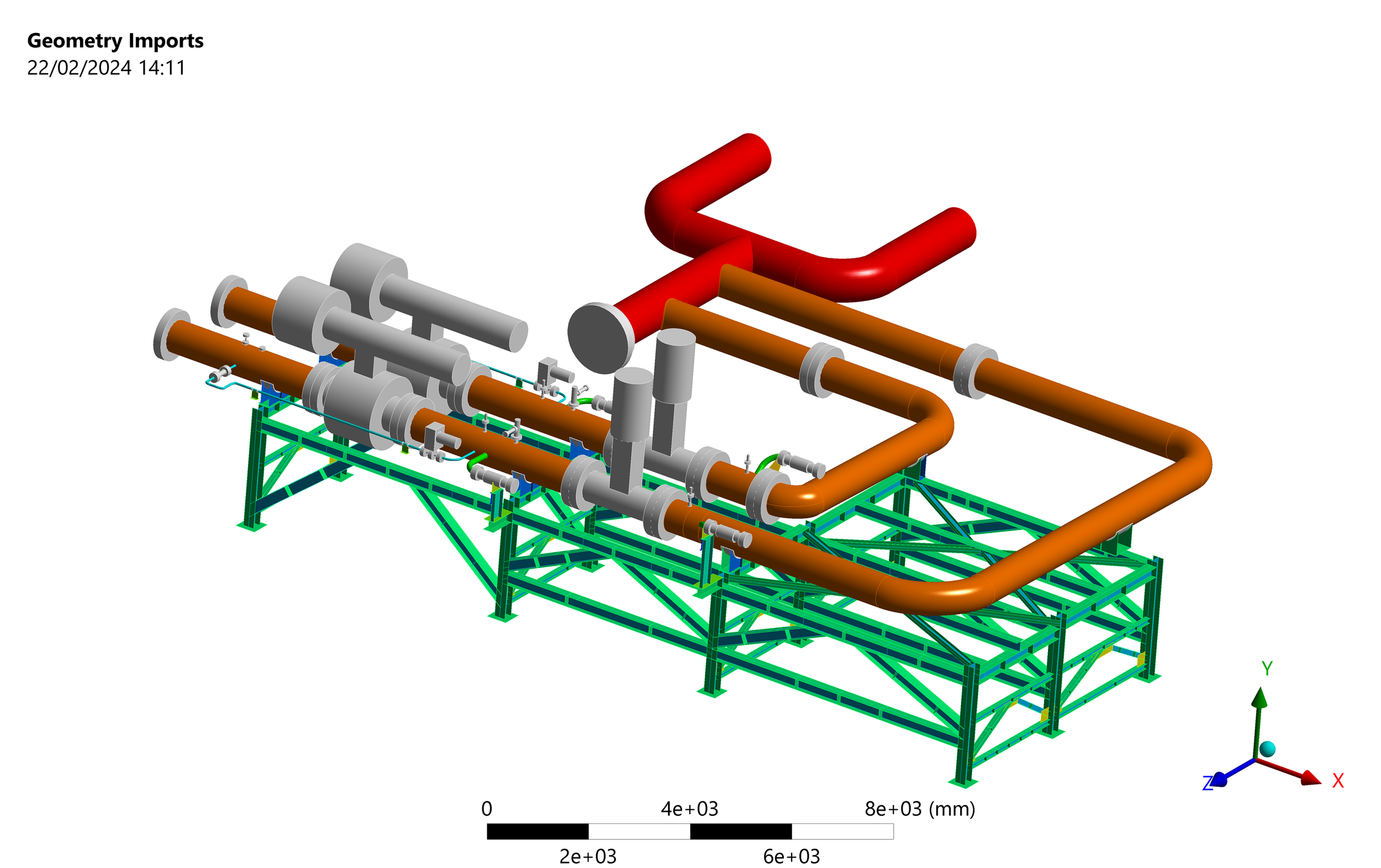

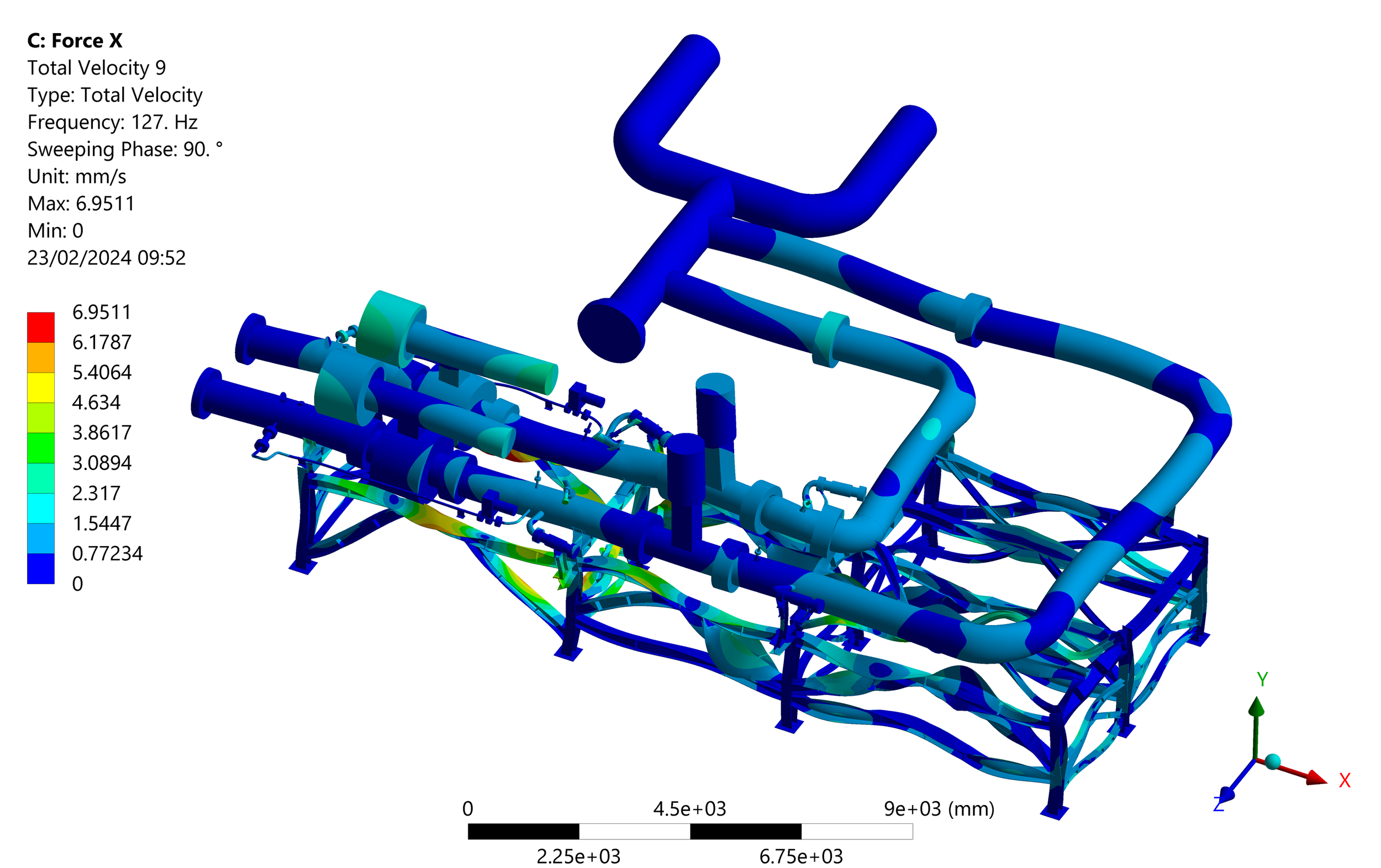

Swift TG Solutions generated a full CAD model of the valves, piping and corresponding structure using the client’s detailed drawings. Modal analysis was performed for four ranges of frequencies: Lower frequency (below 20Hz), mid frequencies (20-44Hz), high frequencies - 100-110Hz and120-135Hz. The response was then compared with sensor data provided by the customer.

Further to this, models with four levels of reinforcement to the supporting structure were also generated as an attempt to mitigate deformations.

Process.

Finite Element Analysis (FEA) for the Onshore Process Industry

Geometry of the piping and structure was modelled in CAD

validation and Delivery.

The study identified structural response modes within the band of the flow‑induced vibrations measured on site, thereby validating the FEA model and the analysis methodology. Deliverables included a comprehensive technical report documenting inputs, assumptions, results and recommendations, and an accompanying presentation for stakeholder review.

Results.

Reinforcement of the supporting structure alone was shown to deliver diminishing returns beyond a certain increase in structural stiffness. Based on the findings of this study, the client reached the conclusion that that the best course of action to address the vibration was to make supporting structure changes as proposed and to implement valve modifications that addressed the root cause of vibration (a cavity within the valve was found to act as a Helmholtz resonator, driving pressure pulsations). This combined approach provides a more durable resolution than incremental reinforcement.

Geometry was analysed and post processed

“Swift TG Solutions understood our priorities and delivered exactly what we needed - on time and with great attention to detail.”