computer aided design (CAD)

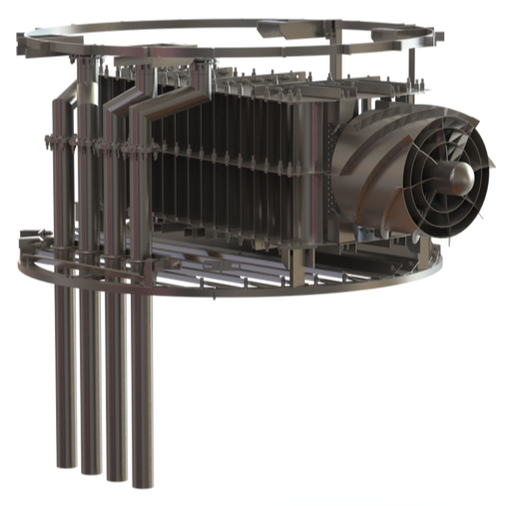

Computer Aided Design (CAD) is the use of 3D computer technology to aid the design of a part or product. CAD solutions maximise innovation and quality to help create exceptional products. CAD enables engineers to visualise and model a product before it has ever left the drawing board - identifying potential problem areas and getting the product ready for production with only a fraction of the time and money required by traditionally run projects.

Step 1 - Creating the Product Design

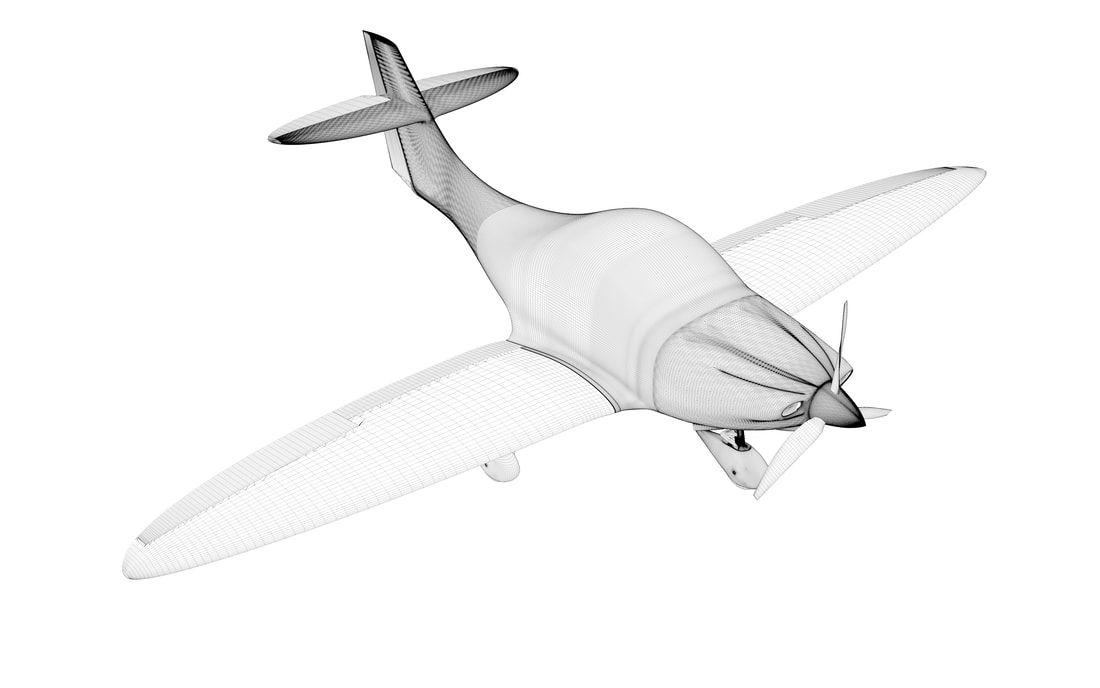

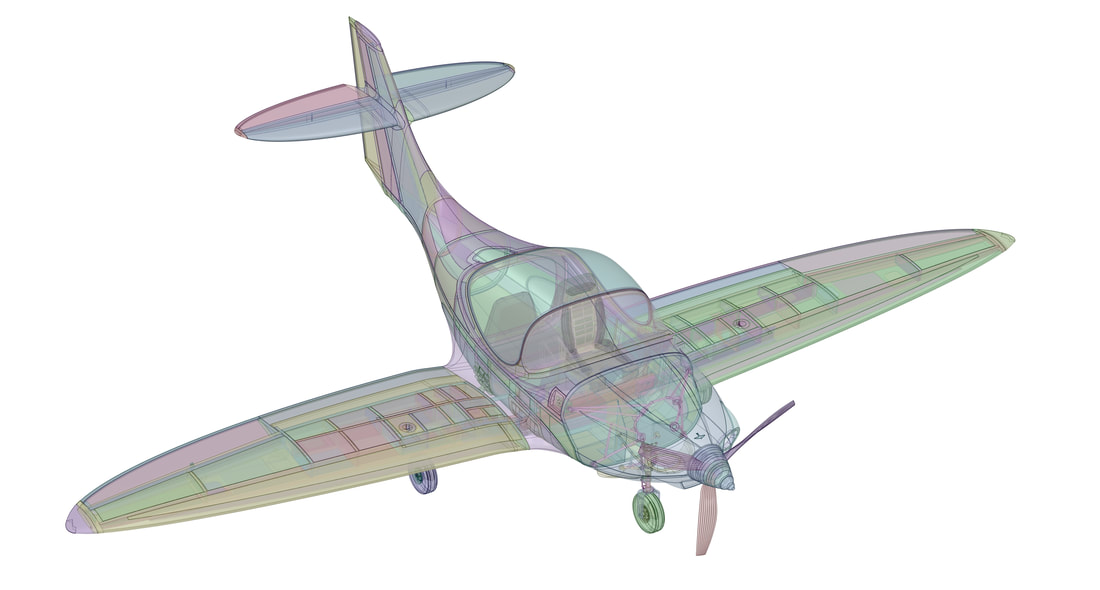

If you are in the early stages of product design, or just have an idea in your head, we can visualise your idea and produce a marketable concept. By using Mesh Modelling, a polygon-based 3D model, we can create a quick model version of your product or idea. We can then apply textures and lighting to your product so that it becomes photo-realistic. This model can quickly be altered, textures and colours can change and your vision of the final product can become closer to reality. Renders of this 3D model can be used in marketing campaigns, fundraising campaigns and advertising. This is the quickest and most cost-effective way to refine your product or idea before moving forward to the next step.

Step 2 - Analysing and Refining the Product

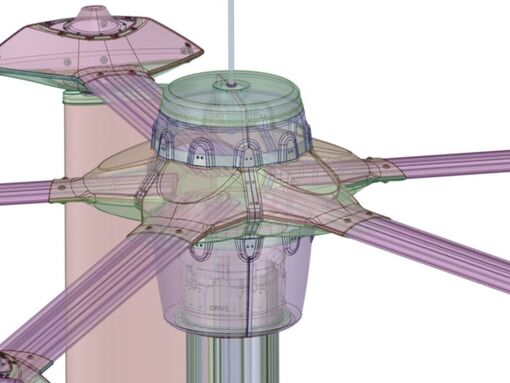

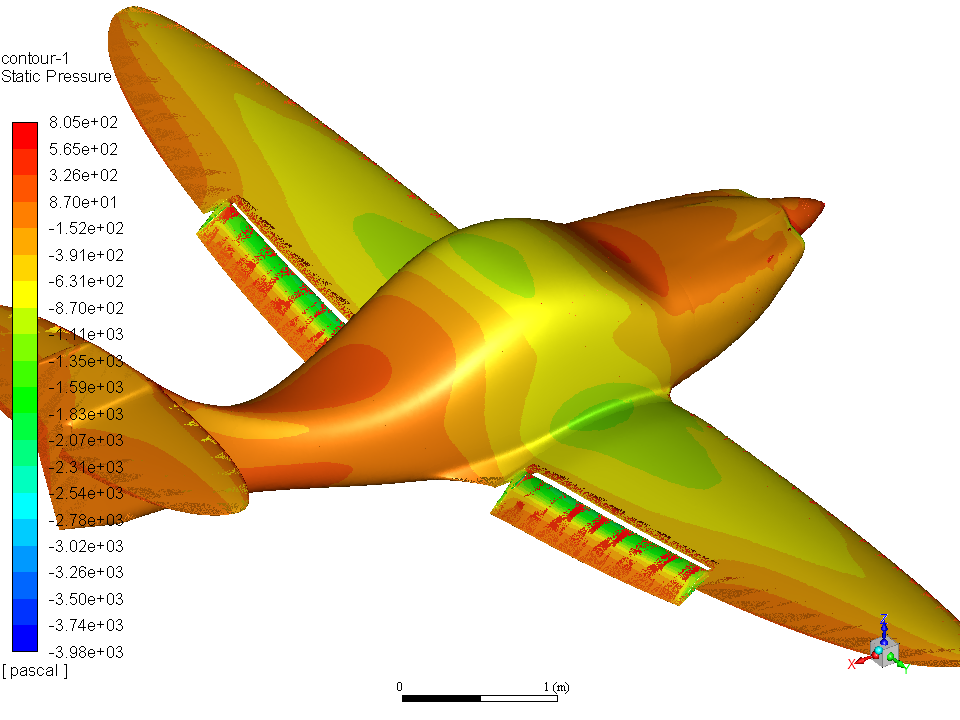

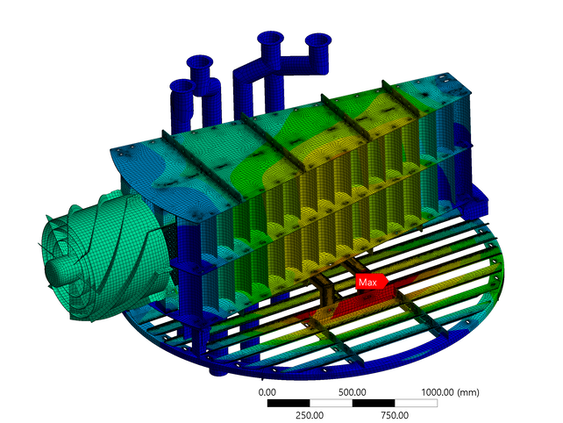

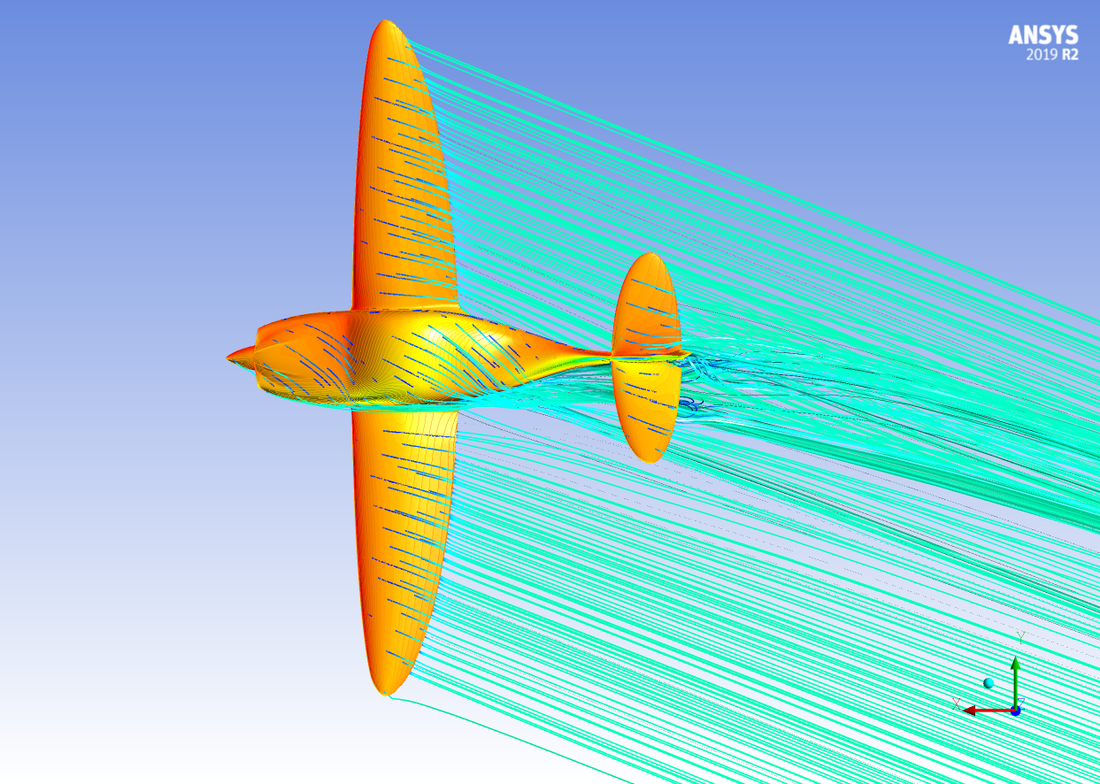

We can take any type of 3D file, including polygon/mesh models, and analyse your product model with accuracy. Using our range of ANSYS CAD Software, including ANSYS SpaceClaim, ANSYS Fluent and ANSYS Structural, together with SolidWorks and Pro/E, we can cover anything from Reverse Engineering and Concept Design through to completed Manufacturing.

We can also evaluate your product using Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) to provide accurate structural and efficiency reports which help to refine and improve your product.

In this step Topology Optimisation can also be performed which is a methodology to strip out all unwanted material from a component by optimising load paths. This effectively removes all unnecessary weight from the product and provides a balance between required product stiffness and material properties. For instance it can be found that the use of a more expensive material will lead to overall cost reductions since less material is needed.

We can also evaluate your product using Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) to provide accurate structural and efficiency reports which help to refine and improve your product.

In this step Topology Optimisation can also be performed which is a methodology to strip out all unwanted material from a component by optimising load paths. This effectively removes all unnecessary weight from the product and provides a balance between required product stiffness and material properties. For instance it can be found that the use of a more expensive material will lead to overall cost reductions since less material is needed.

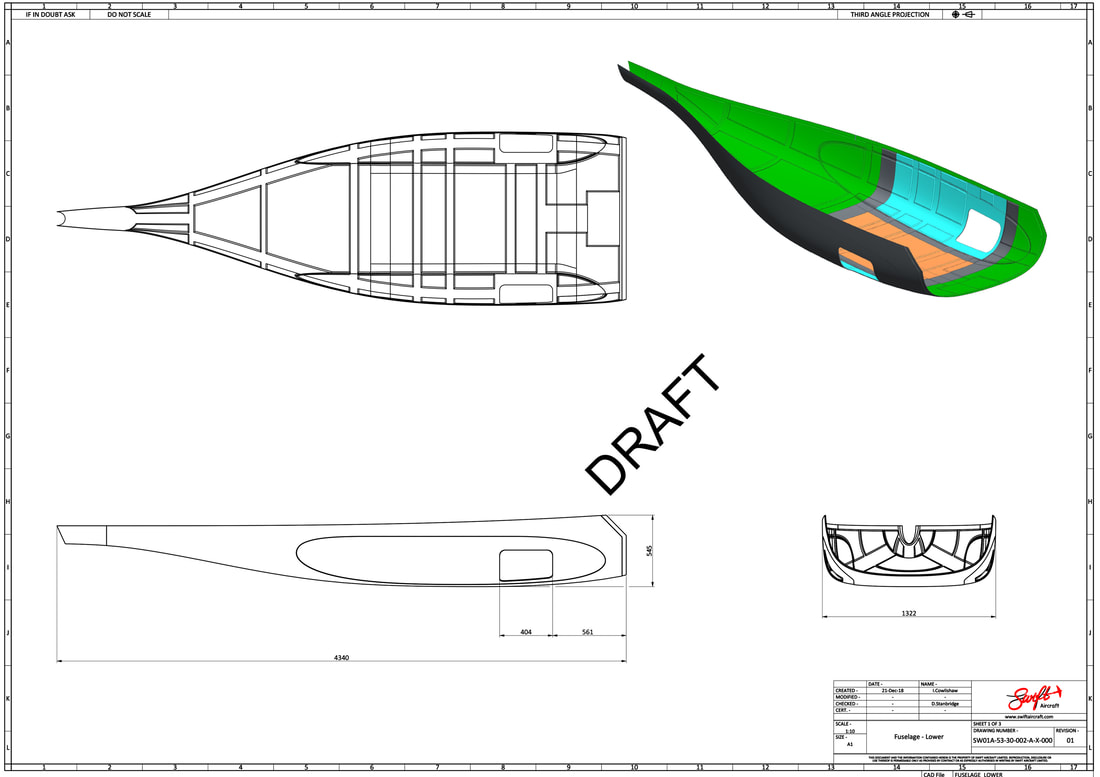

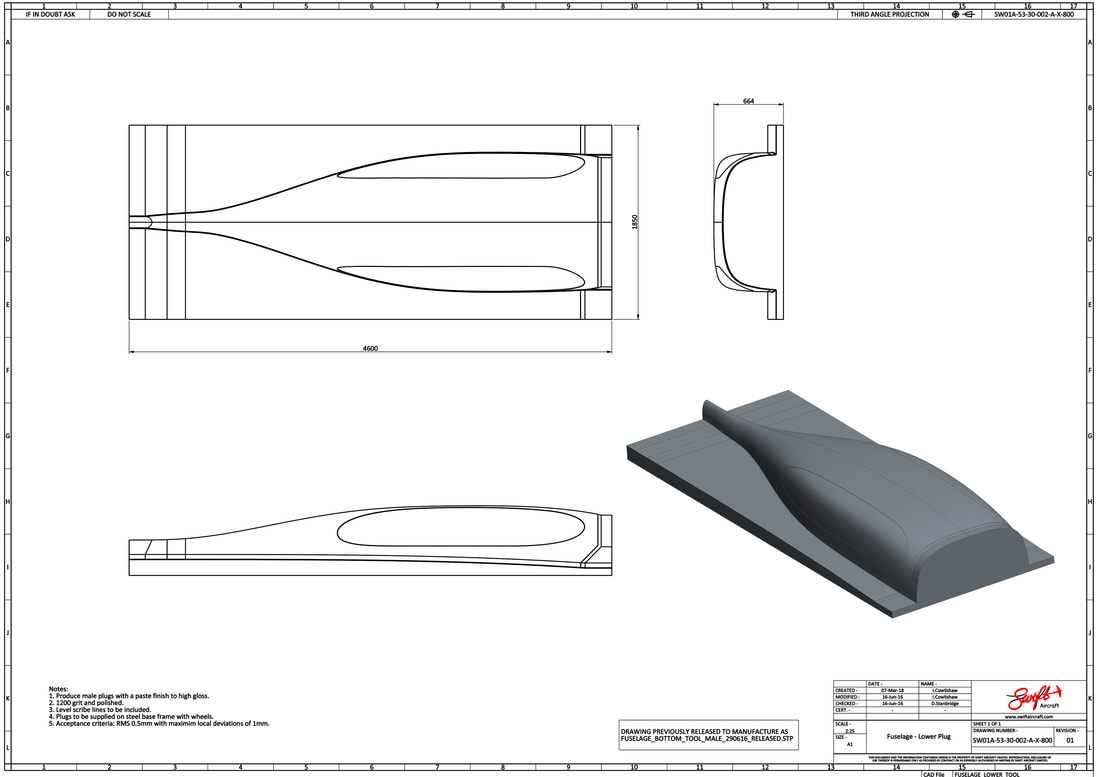

Step 3 - Preparation for Manufacturing

Once a product has been modelled and tested, it needs to be prepared for manufacturing. We use SolidWorks and Pro/E to create drawing files which are extremely important for accurate and high-quality manufacturing of your product.

We also have in-group fabrication capability. Having this direct expertise allows us to provide a final design which best suits the required method of manufacture and is particularly important when considering the aesthetics and finish quality of a product.

We also have in-group fabrication capability. Having this direct expertise allows us to provide a final design which best suits the required method of manufacture and is particularly important when considering the aesthetics and finish quality of a product.